LGC ARMI now has new analytical capabilities including ICP-OES, ICP-MS and WDXRF in our Manchester, NH facility. Our ISO 17025 laboratory is also equipped with the new ColdBlock rapid digestion system as well as other conventional sample preparation equipment.

New ARMI Analytical Capabilities

[fa icon="calendar'] Dec 20, 2017 2:53:35 PM / by Dave Coler posted in ICP, WDXRF, Custom Reference Materials

AISI Grades 1045, 4130, 4820 and ASTM A36 Now Available

[fa icon="calendar'] Dec 5, 2017 2:42:08 PM / by Dave Coler posted in carbon steel, low alloy steel, AISI 4130, AISI 4820, AISI 1045, A36

ARMI is pleased to release four new steel certified reference materials. These include; IARM 200D (AISI 1045) , IARM 143F (AISI 4130) , IARM 155F (AISI 4820) and IARM 213D (ASTM A36).

New Steel Certified Reference Materials

[fa icon="calendar'] Nov 7, 2017 10:38:12 AM / by Dave Coler posted in carbon steel, low alloy steel, metal CRMs

ARMI is pleased to announce the release of 5 new steel certified reference materials. These new reference materials include 5 low alloy steels; AISI grades 4140, 4330, 4340, E52100 and 5Cr ½Mo.

As always these reference materials are available in three different forms depending on your analytical technique; 38mm diameter x 3mm thickness for XRF, 38mm diameter x 19mm thickness for arc spark OES or as chips for analysis by ICP or AA.

The complete listing of the new reference materials are shown in the table below along with links to the certificates of analysis. You can also check out our new products page to see all of our latest CRM's.

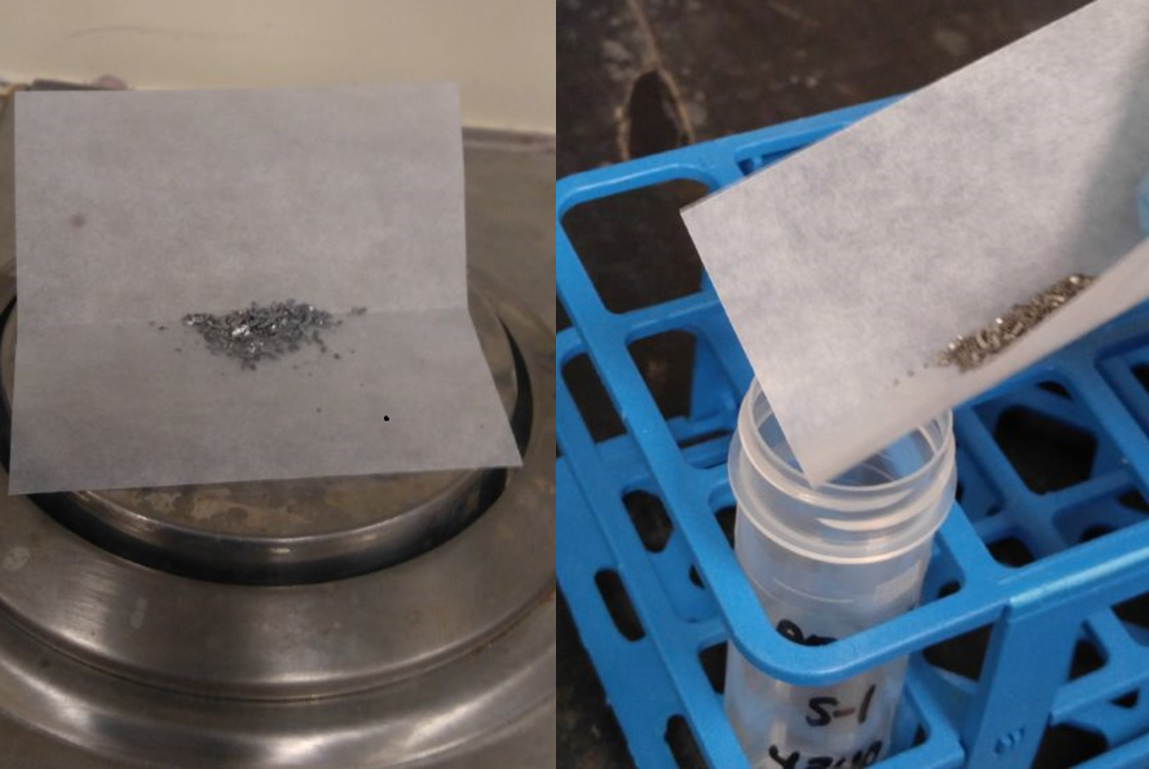

Reducing Contamination in the Preparation of Metal Alloys for Analysis by ICP

[fa icon="calendar'] Jul 31, 2017 8:00:00 AM / by Susan J. Evans Norris posted in Sample Preparation, metal alloys, ICP

We have received several questions regarding the best approach to cleaning solid samples and standards that have been prepared as chips for analysis by a total dissolution technique, such as ICP-OES or ICP-MS. Let’s first discuss common approaches for sampling, and then appropriate methodologies for ensuring chips are clean and free from contamination.

New Sample Preparation Technique for Metal Alloys

[fa icon="calendar'] Jul 27, 2017 11:24:47 AM / by Dave Coler posted in sample digestion, metal CRMs, Microwave digestion, icp sample preparation

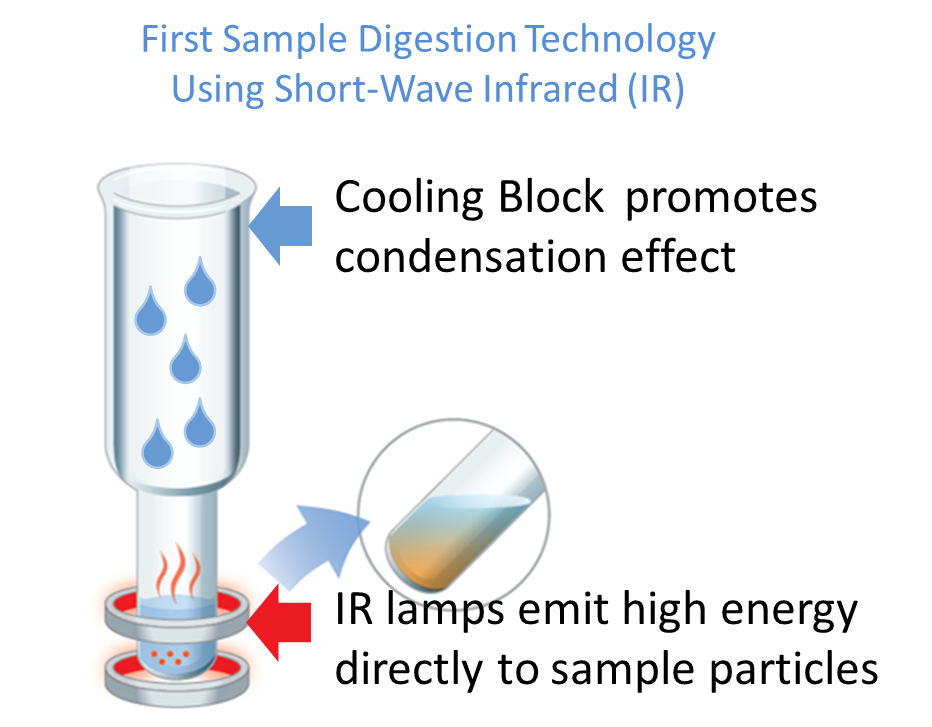

In a previous blog post “How to prepare metal alloy samples for analysis by ICP-OES or ICP-MS”, my colleague Sue Evans Norris described the traditional methods for the sample preparation of metal alloys by ICP. At ARMI, we are always looking for ways to improve the status quo and recently discovered a new sample preparation technology for the rapid digestion of metal alloys using short-wave infrared radiation. This technology, promoted by a Canadian company called ColdBlock, claims their instrument can digest metal alloys faster than current techniques while eliminating the need for dangerous acids such as hydrofluoric and perchloric acid.

New Nickel Alloy CRM's

[fa icon="calendar'] Jul 21, 2017 4:23:12 PM / by Dave Coler posted in nickel alloys, monel

LGC ARMI announces the release of a new set of Nickel alloy Certified Reference Materials.

These include:

- IARM 25D - Alloy 20

- IARM 51D- Alloy 400

- IARM 52D - Alloy K500

- IARM 157D - AL6XN

- IARM 239C- Alloy 225

As always these reference materials are available in three different forms depending on your analytical technique; 38mm diamater x 3mm thickness for XRF, 38mm diameter x 19mm thickness for arc spark OES or as chips for analysis by ICP or AA.

Want to learn more about thes reference materials ? You can download the certificates of analysis using th hyperlinks above and check out our new products page for information on these and other recently released products.

New Aluminum SUS available-IARM 220G

[fa icon="calendar'] Jun 28, 2017 4:37:15 PM / by Dave Coler

Set Up Samples (SUS)

Set up Samples were described in a previous blog post by Charlie Hodges entitled “How to Choose the Correct Aluminum Reference Material for Your Application” but in general, they are homogeneous reference materials used for daily drift correction or standardization or slope correction, typically for arc spark optical emission spectroscopy. These materials are homogeneous and are usually provided with a certificate of analysis showing the approximate chemical composition but differ from a certified reference material in that there is no supporting statistical data. These types of materials offer a low cost alternative to consuming expensive CRM’s for daily drift correction.

How to Prepare Metal Alloy Samples for Analysis by ICP-OES or ICP-MS

[fa icon="calendar'] Jun 23, 2017 5:57:49 PM / by Susan J. Evans Norris posted in Sample Preparation, metal alloys, ICP, coldBlock, Microwave digestion, HotBlock

Metal alloys are commonly analyzed using solid sampling techniques such as Arc/spark optical emission spectroscopy (A/S OES), X-ray Fluorescence Spectroscopy (both Energy Dispersive (ED-XRF) and Wavelength Dispersive (WD-XRF)), and X-ray Diffraction (XRD). These techniques provide fast analysis with little or no sample preparation required, and can be provided as portable units, and in the case of XRF, hand-held units, for maximum flexibility. These techniques also are considered non-destructive in that the metal alloy is left largely unchanged after analysis, and is available for further testing or archiving.

New Nickel and Titanium Alloy CRM's

[fa icon="calendar'] Jun 7, 2017 8:00:00 AM / by Dave Coler posted in Titanium Alloys, nickel alloys, 625 alloy, 718 alloy

Its college graduation season here in the US and we here at ARMI are proud to announce the graduation of out next batch of certified reference materials for the metals industry. The graduates are IARM 54G, IARM 56H and IARM 271B.

54G is a 625 Nickel alloy and replaces 54F. 56H is a 718 Nickel alloy and replaces 54G. 271B is a 5-2.5 Titanium alloy.

Improve your ICP-OES Performance by using an Internal Standard

[fa icon="calendar'] Jun 2, 2017 12:40:33 PM / by Susan J. Evans Norris posted in Certified Reference Materials, metal alloys, ICP

The use of an Internal Standard (IS) can significantly improve both the accuracy and precision of your ICP-OES analytical results. This post addresses: how internal standards work, how to select an appropriate IS element, and how this methodology can be easily incorporated into your lab’s analytical procedures.