In a previous blog post “How to prepare metal alloy samples for analysis by ICP-OES or ICP-MS”, my colleague Sue Evans Norris described the traditional methods for the sample preparation of metal alloys by ICP. At ARMI, we are always looking for ways to improve the status quo and recently discovered a new sample preparation technology for the rapid digestion of metal alloys using short-wave infrared radiation. This technology, promoted by a Canadian company called ColdBlock, claims their instrument can digest metal alloys faster than current techniques while eliminating the need for dangerous acids such as hydrofluoric and perchloric acid.

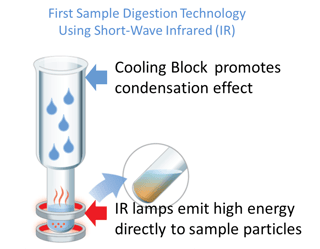

This digestion technology uses a short-wave infrared radiation to energize the sample and a cooling block to create a condensation effect. In this system, the sample is loaded into a quartz tube along with a relatively small amount of acid. The tube is loaded into the cooling block, and the bottom of the digestion vessel is exposed to an infrared lamp. Below is a diagram from the ColdBlock website showing the technology and the ColdBlock digestion system.

They claim that samples can be dissolved faster (15 minutes) than current techniques without the need for dangerous hydrofluoric or perchloric acids. An additional benefit is that the digestion vessels are inexpensive compared with those for microwave digestion and do not require the extensive cleaning needed for Teflon vessels.

We were intrigued by this technology and decided to put it to the test.

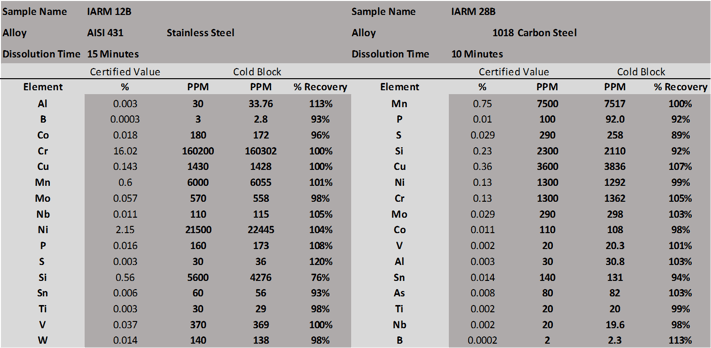

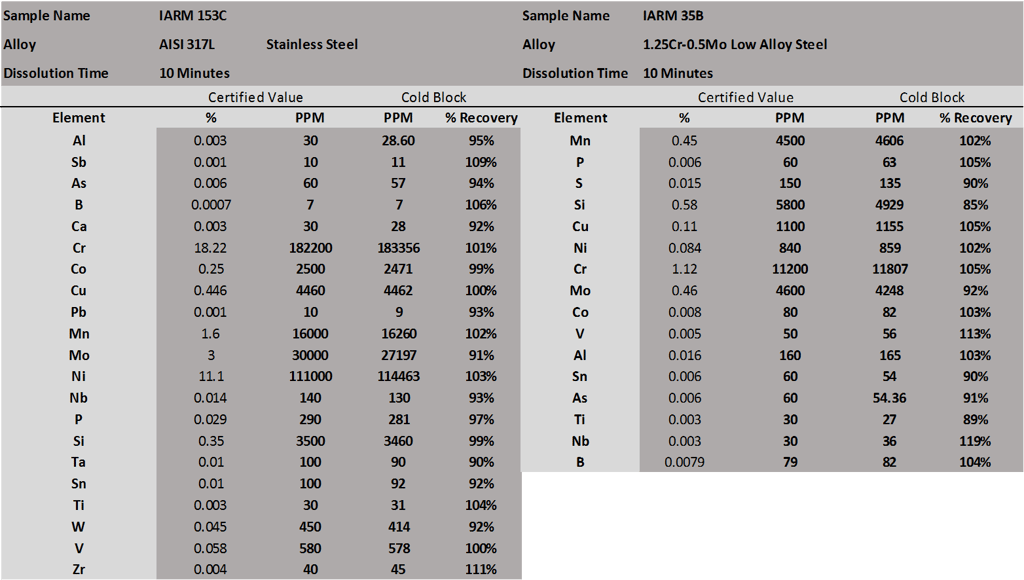

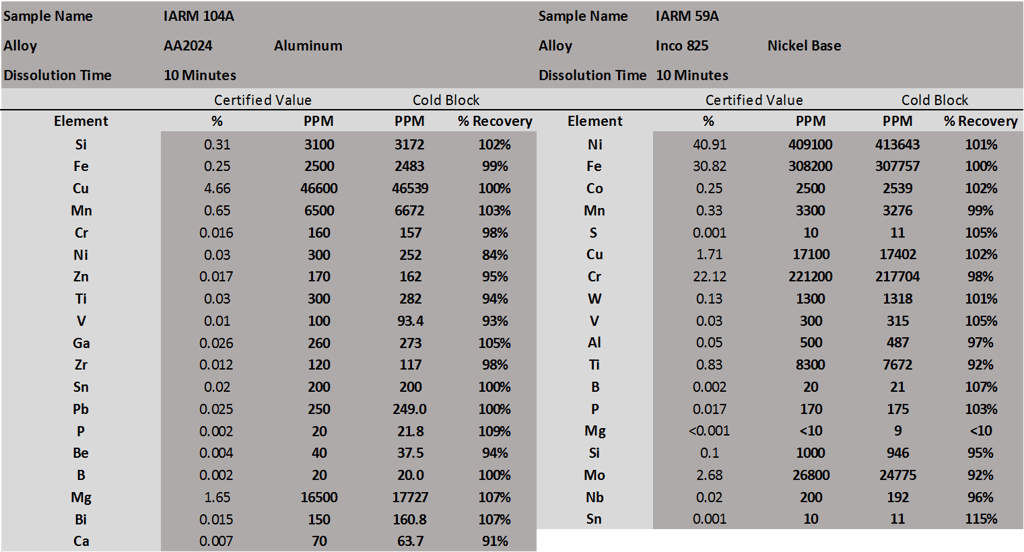

We sent ColdBlock seven metal alloy certified reference materials to digest using their new technology and analyze by ICP-OES. These reference materials included steel, nickel, copper and aluminum alloys.

- IARM 153C - 317L stainless steel

- IARM 28B - 1018 carbon steel

- IARM 35B – 1.25Cr-0.5Mo low alloy steel

- IARM 12B – 431 stainless steel

- IARM 59A– Inco 825 nickel alloy

- IARM 104A– AA2024 aluminum alloy

- IARM 211A – Magnolia B copper alloy

The Results

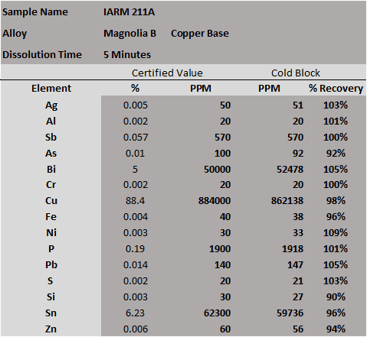

After a few weeks, the data came back along with a video of one of the samples being digested. According to the ColdBlock protocol, all digestions were performed using 1g of sample and 30ml of aqua regia acid. Digestion times varied from 5 to15 minutes. The data are shown below.

Generally, the data match up well with the certified values. Recovery rates vary more widely at the lower ppm level; overall, the initial data looks quite good for an initial test. The technology looks promising especially given the benefits of faster dissolution times, easier cleaning, less expensive consumables and the ability to limit or remove the need for hydrofluoric or perchloric acid completely. We are still testing this technology for metal alloys with more difficult alloys so stay tuned...

ARMI is now the exclusive distrobutor of ColdBlock digestions systems for the metals industry