Metal alloys are commonly analyzed using solid sampling techniques such as Arc/spark optical emission spectroscopy (A/S OES), X-ray Fluorescence Spectroscopy (both Energy Dispersive (ED-XRF) and Wavelength Dispersive (WD-XRF)), and X-ray Diffraction (XRD). These techniques provide fast analysis with little or no sample preparation required, and can be provided as portable units, and in the case of XRF, hand-held units, for maximum flexibility. These techniques also are considered non-destructive in that the metal alloy is left largely unchanged after analysis, and is available for further testing or archiving.

However, there can be limitations to these techniques, both in the terms of the total number of elements analyzed and in the sensitivity of the technique. The number of elements that are analyzed can be dictated by the spectrometer layout or by the standards available for calibration. Sensitivity in these techniques is commonly in the low ppm range.

ICP-OES or ICP-MS can provide expanded element coverage and sensitivity ranges several orders of magnitude lower than XRF or A/S OES. Synthetic standards can be easily prepared using aqueous multi-element mixes and allow the analysis of 70+ elements. However, both techniques require that the sample be presented as an aqueous solution. For metal alloys, this means that the sample must be digested completely prior to analysis. The following examples provide an overview of useful approaches for total dissolution.

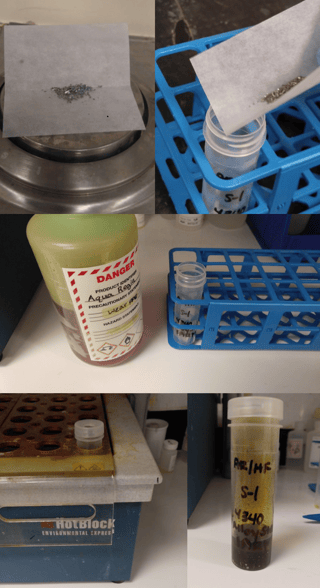

The acid digestion of metal alloy samples can be performed using conventional hot-plate techniques or commercially available microwave digestion apparatus (NOTE: Use only microwave units specifically designed for laboratory use; kitchen microwave units are not suitable or safe for laboratory use and should never be utilized.) Always follow the specific instructions provided by the microwave digestion manufacturer. A third option is a new ColdBlock technology that uses shortwave IR lamps to heat the sample directly leading to sample digestion times of minutes compared to hours with conventional sample preparation techniques. This option also has the benefit of easier cleaning between samples compared with microwave digestion. You can read more about this in one of our other blog posts , The Evaluation of a New Sample Preparation Technique for Metal Alloys.

ColdBlock Digestion System

Many manufacturers also provide application notes for various sample types, and may include metal alloys. For that reason, this discussion will focus primarily on conventional hot-plate digestion approaches, but these can also be applicable for microwave digestions.

Optimum sample sizes are typically 0.5-1.0 grams, and the sample should represent a homogeneous sub-sample of the metal alloy being sampled. Samples larger than 1g are more difficult to digest and require more time. Samples less than 0.5g may not be a representative sample of the alloy, particularly if there is any element segregation possible in the alloy. Digestions should be performed in acid-resistant labware, such as Teflon beakers. The use of glass is not recommended, as elements such as B or Si can leach during the digestion procedure and cause contamination of the sample.

Hot Block Digestion

-

Carbon and low alloy steels, a nitric acid (HNO3) or a nitric/hydrochloric acid (HCl) digestion procedure can be utilized for complete dissolution of the alloy. (CAUTION: Working with concentrated acid requires appropriate safety training prior to use; only laboratory personnel trained in the use of concentrated acids and the required protective safety gear, including lab coat, acid-resistant gloves, and face shields, should utilize this digestion procedure). Nitric acid alone can be used for elemental silver, copper, zinc and iron, in a 1:1 ratio of HNO3 and H2O. The use of aqua regia (a mixture of concentrated nitric acid and concentrated hydrochloric acid in the molar ratio of 1 part nitric to 3 parts hydrochloric) is necessary for the dissolution of any precious metals contained in the alloy, or for low alloy steels. Gentle heating on a hot plate can increase the digestion rate.

Carbon and low alloy steels, a nitric acid (HNO3) or a nitric/hydrochloric acid (HCl) digestion procedure can be utilized for complete dissolution of the alloy. (CAUTION: Working with concentrated acid requires appropriate safety training prior to use; only laboratory personnel trained in the use of concentrated acids and the required protective safety gear, including lab coat, acid-resistant gloves, and face shields, should utilize this digestion procedure). Nitric acid alone can be used for elemental silver, copper, zinc and iron, in a 1:1 ratio of HNO3 and H2O. The use of aqua regia (a mixture of concentrated nitric acid and concentrated hydrochloric acid in the molar ratio of 1 part nitric to 3 parts hydrochloric) is necessary for the dissolution of any precious metals contained in the alloy, or for low alloy steels. Gentle heating on a hot plate can increase the digestion rate. - Stainless and other high temperature steels and hastelloys (nickel and cobalt based alloys), a mixed acid approach including hydrofluoric acid (HF) is typically necessary for complete digestion. (CAUTION: All appropriate safety precautions must be observed when using hydrofluoric acid, including the availability of calcium gluconate or similar hydrofluoric-specific agent for use in the case of accidental exposure. Only laboratory personnel with specific safety training in the use of HF should utilize this digestion procedure). An effective mixture is 7:3:1 HNO3/HCl/HF, combined with heating and/or pressure. Whenever HF is utilized, there is the potential for the loss of volatile fluorides such as SiF4 and other highly fluorinated species; if Si, As Se, Te, or Sb are desired analytes the digestion should be conducted in a closed digestion apparatus.

- Titanium alloys and other alloys containing high levels of refractory elements, a mixture containing greater amounts of HF is required. A mixture of 1:1:1 HNO3/HF/H20 can be utilized with heating for the dissolution of these alloys.

- Aluminum alloys are best digested with 1:1 H2O/HCl with water being added first and the HCl added slowly. Depending on surface available they can be quite reactive and/or have a delayed reaction. Gentle heating, if necessary, to complete dissolution. If Si, Ti or any refractory elements are part of the analysis scheme then the sample preparation would be 5mlf HF with 1-2 mls HNO3 added, drop wise, to keep the reaction slow as to not lose Si with heat from the reaction.

Microwave Digestion

In all digestions, it is very important to incorporate an appropriate QC sample, using the exact same sample digestion technique to prepare it as is used for the unknown samples. The QC sample should be a well characterized or certified reference material of the same type and general composition as the unknown samples, with as many of the analyte elements certified as possible. This will help to verify the suitability of the chosen digestion procedure for each analyte. Poor recoveries on the QC analytes can provide information as to possible incomplete dissolution or volatilization of those elements in the sample alloy. Refinements to the acid mix, heating, and pressure protocol can then be made to prevent such losses. In some circumstances, it may be necessary to prepare two different acid digestions of the sample to provide complete recovery of all analytes.

In summary, ICP-OES and ICP-MS can provide significant advantages to conventional solid-sampling techniques. Although the sample preparation step is more time-consuming and requires the use of concentrated acids, the analysis can provide much improved sensitivity and a wider range of analytes. Samples characterized in this fashion can then be used as appropriate calibration or QC samples in a solid sampling based analysis procedure.