Aluminum reference materials are selected using several criteria: by grade, by major elements, or by concentration specifications. It can be a bit confusing to find the best reference material for your application. In this post, I’ll describe various types of aluminum reference materials and offer some suggestions on choosing the best option to meet your objectives.

Most aluminum alloy certificates of analysis (CofAs) list the major alloying elements first: Si, Fe, Cu, Mn, Mg, Cr, Ni, Zn and Ti. These are the elements that vary in concentration in order to create the array of both cast and wrought alloys available. Typically, any other certified elements are listed alphabetically on the CofA.

There are several types of aluminum reference materials available; each with its own unique applications.

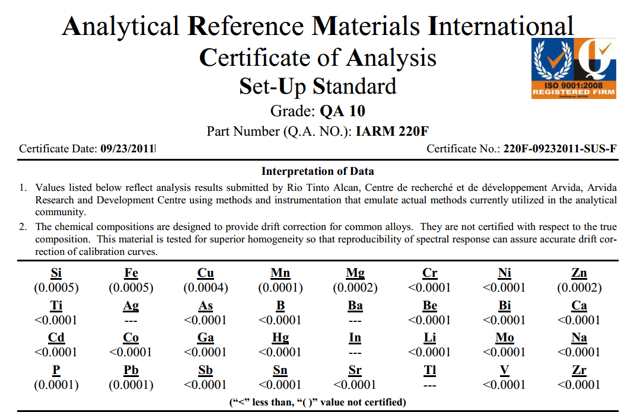

Set-up, or setting-up samples (SUS) are provided with simple certificates. They have only approximate values reported with no supporting statistical data included. SUS material is homogeneous by design, so that the intensities gathered from using these materials are consistent. SUSs offer a low-cost option for daily standardization or slope correction and should never be used as part of a calibration suite because the values are not sufficiently certified for that purpose.

Binaries are another type of specialty reference material. Single elements are combined with the aluminum base material. These materials are typically used to extend calibration curves for select elements beyond typical factory calibration ranges. There are no other elements that can potentially create interferences when calibrating with either spark emission or XRF. These standards are typically considered to be reference materials, as they do not have certificates with uncertainty data provided.

CRMs or fully certified reference materials are available in various configurations. These materials are most often used for occasional calibration. The high cost of CRMs generally preclude daily use for slope correction, but can and are used for this purpose if no other proper standards are available.

You can choose CRMs with only the major elements certified. There are versions that include these majors in a high-purity matrix with no impurity-level elements present to minimize potential interferences. Others have the major elements certified with uncertified trace elements present. In either case, these do not offer the full range of possible certified elements found in aluminum materials.

There are full CRMs that offer certificate values for the full range of elements, from majors to minors. These CRMs offer the best information to help fully calibrate your instrument for both major and minor elements.

The three largest producers of aluminum reference materials are Rio Tinto Alcan and Aconic (Alcoa) and Suisse Technologies. In addition, SUS samples are also available from ARMI, SUS Nell and others.

If you need assistance in choosing an aluminum reference material, we are happy to help.