Our ARMI | MBH team is continuing their work to develop more new products to ensure that we can provide the products you need for your analytical testing. I am proud to announce the release of 3 new Steel CRMs for our industrial's portfolio. included in this are two Nitrogen steels and a precipitation hardening steel . If you want to learn more about any one of products listed you can simply click on the links to view the certificate of analysis.

New Steel CRMs for August 2020 - 2 N and 1 Precipitation Hardening

[fa icon="calendar'] Aug 25, 2020 9:45:00 AM / by Kim Halkiotis posted in Certified Reference Materials, metal alloys, stainless steel alloys, metal CRMs, Steel CRMs

New Steel CRMs for May 2020 - High N, Precipitation Hardening and Austenitic

[fa icon="calendar'] May 11, 2020 9:15:00 AM / by Kim Halkiotis posted in Certified Reference Materials, metal alloys, stainless steel alloys, metal CRMs, Steel CRMs

Here at ARMI | MBH we have been busy looking through data and certifying new material. I am proud to announce the release of 5 new Stainless Steel CRMs this month. (click on the links in the names of each part to see the certificates of analysis.)

New Steel CRMs for April 2020 - Grades F9, 15-5PH, 1020 and 1050

[fa icon="calendar'] Apr 16, 2020 1:17:17 PM / by Kim Halkiotis posted in Certified Reference Materials, metal alloys, stainless steel alloys, carbon steel, low alloy steel, metal CRMs, Steel CRMs

Here at ARMI | MBH we have been busy looking through data and certifying new material. I am proud to announce the release of 4 new Steel CRMs this month. (click on the links in the names of each part to see the certificates of analysis.)

New Reference Materials for December 2019

[fa icon="calendar'] Dec 3, 2019 10:08:00 AM / by Dave Coler posted in stainless steel alloys, low alloy steel, Cast Iron, copper base alloys

Here at ARMI | MBH we are excited to report that we have completed the integration of MBH Analytical into our Manchester, NH facilities. Throughout the integration the teams have continued to develop new products for the combined portfolio of metal alloy reference materials. Now as we begin December, I am pleased to introduce 7 new CRM products.

CRMs for Inconel 690, Haynes® 282® and Incoloy 25-6Mo

[fa icon="calendar'] Jun 19, 2018 4:55:44 PM / by Dave Coler posted in stainless steel alloys, nickel alloys

ARMI introduces three new certified reference materials for Inconel 690, Haynes® 282® and Incoloy 25-6Mo.

New ARMI Reference Materials

[fa icon="calendar'] Mar 8, 2018 2:37:07 PM / by Dave Coler posted in Certified Reference Materials, stainless steel alloys, Custom Reference Materials

Developing new reference materials can be a time consuming process often requiring several years to complete. This means that reference material development typically lags well behind the introduction new metal alloys created to meet the needs of increasingly demanding industrial applications. This disparity creates a problem for chemists working with analytical methods such as XRF, ICP and OE, as these are comparative techniques and require reference materials to calibrate and validate.

How to Digest 316 Stainless Steel for ICP Analysis Using the ColdBlock Digestion System

[fa icon="calendar'] Jan 30, 2018 5:40:25 PM / by Dave Coler posted in stainless steel alloys, icp sample preparation

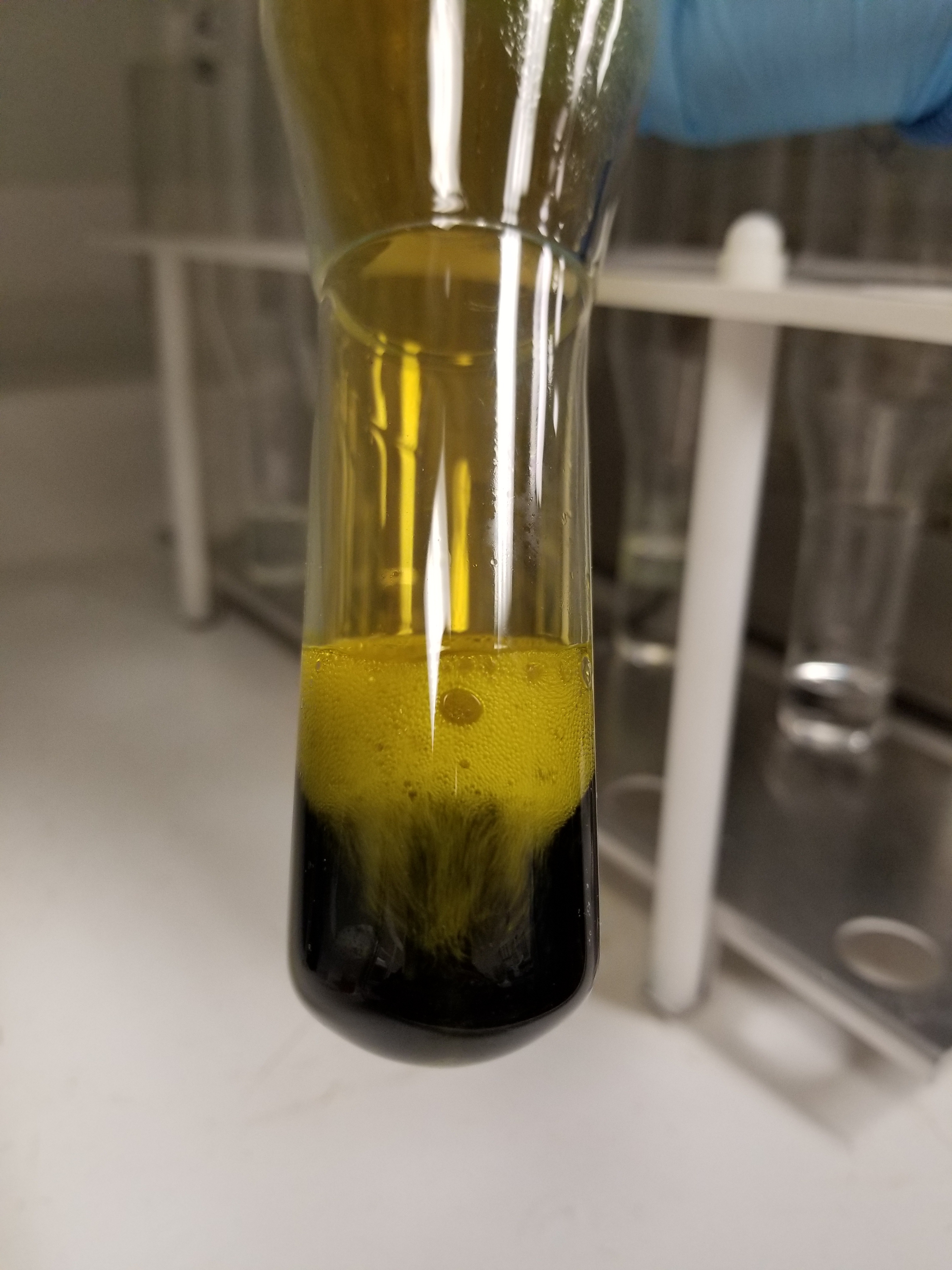

The ColdBlock system uses infrared radiation to rapidly digest metal alloy samples and a cooling block to condense out escaping vapors minimizing the loss of volatile elements. Our preliminary results, detailed in a previous blog post (A New Sample Preparation Technique for Metal Alloys), looked promising so we are now conducting validation studies with IARM CRM’s of various alloys. This post details our validation study using CRM IARM 5I, a Grade 316 stainless steel alloy.

Digestion Procedure

5 separate 0.5g aliquots of CRM IARM 5I were prepared using 20ml of aqua regia in a quartz digestion tube. The 5 digestion vessels were loaded into a 6 position ColdBlock digestion system and digested for 15 minutes at 28% power. The digested samples were diluted to a total volume of 50ml using deionized water and transferred to a centrifuge tube. 1 ml of HF was then added to each centrifuge tube to stabilize the solution. The samples were then analyzed on a Spectro Arcos ICP-OES in our laboratory. The results are detailed below. The reproducibility of each of the 5 digestions is very good, and the average values agree well with the certified values for all elements including Si and volatile elements such as As and S. We will be posting the resuts of validation studies on other alloys in the near future so subscribe to our blog to be sure you are automatically notified.

If you would like to learn more about this technology you can visit our product page Learn More

New Product Release: IARM 282A and 4F

[fa icon="calendar'] Apr 12, 2017 12:43:49 PM / by Dave Coler posted in XRF, metal alloys, stainless steel alloys, Haynes alloys

LGC ARMI is pleased to announce the release of two new standards, IARM 282A and IARM 4F.

These reference materials are available in three different forms depending on your analytical technique; 38mm diamater x 3mm thickness for XRF, 38mm diameter x 19mm thickness for arc spark OES or as chips for analysis by ICP or AA.