The production of metal alloy parts is increasing being done using additive manufacturing (3D printing) processes. 3D metal printers use a metal alloy powder that is fused by a laser in depositional layers 30-50µm thick. The part is thus progressively built up layer by layer until the desired form is completed. This technology is now commonly being applied to the production of mission critical components in the aerospace medical industries. Verifying the quality of the powder material is an important quality control step in the process. Our certified reference materials can assist with that process.

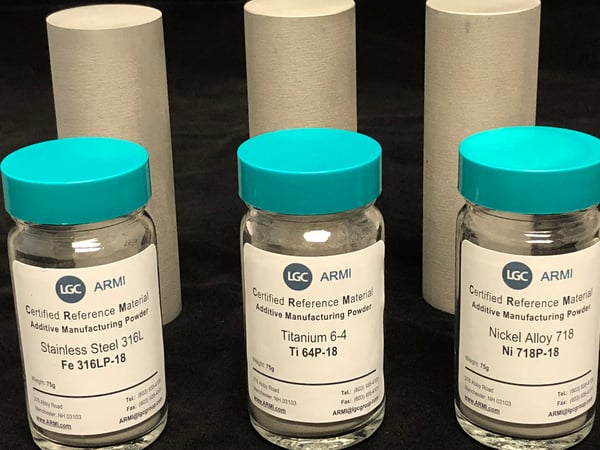

Our CRM’s are produced from metal powders used in fusion bed printing process and are certified for a range of major and trace elements as well as provide informational values for additional trace elements. These reference materials are available for the most common metal alloy grades used in the additive manufacturing process including stainless steel 316L, Inconel 718 and Titanium 6-4.

There are several types of 3D metal printing technologies, but most use a fine metal powder that is then fused by a laser and the part is built up layer by layer. The example below shows a laser bed fusion printer printing stainless steel cylinders from a grade 316L powder. In this example the layers are built up 30 µm at a time.

Given the importance of verifying the quality of parts printed from these powders, we introduce the first certified reference materials for metal additive manufacturing processes. These first reference materials are produced from powder developed for fusion bed printers and include three of the most common grades using in printing today.

These CRM ‘s includes a stainless tell grade 316L, a Titanium 6-4(grade 5) and an Inconel 718. These powders are appropriate for analysis using ICP-OES, ICP-MS and can be rapidly digested for analysis using the ColdBlock sample preparation system.

Visit our new product page to view and download the certificates of analysis for these products.