If you analyze iron-based materials using Spark OES, you are likely familiar with set up samples (SUS). But do you know why set up samples are so critical to your analysis?

All optical emission spectrometers are prone to some degree of intensity drift over time, and because these techniques are comparative, this drift needs to be measured and corrected in order to maintain high quality analytical results.

An SUS is a sample that is typically run on your spark system daily to correct the slope of the calibration lines, correcting for any change in intensity that occurs in the system from day to day. A good SUS is a homogeneous material that will produce a consistent signal over time, meaning that any observed variation in the signal can be assumed to be due to instrument drift, which is then corrected using an intensity factor. With low level analysis of the trace or tramp elements in high purity iron, finding an appropriate SUS to monitor the low level elements can be difficult. Obtaining a stable sample of high purity iron is critical for good long-term precision of all of the minor elements in the method. Once a suitable sample is located, daily analysis equates to a high sample usage, and a can result in a high replacement rate for the material.

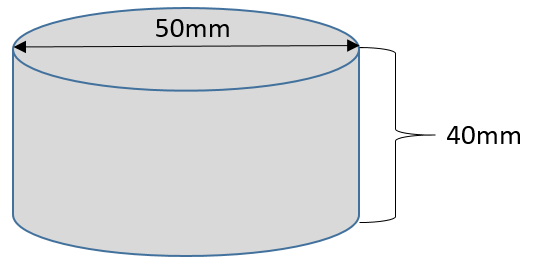

ARMI | MBH is proud to introduce a new, high purity iron SUS; MBH-RE12-20. This new iron SUS is provided as a 50mm diameter disk 40 mm in height, providing a large surface for multiple sparks, and sufficient height to allow for numerous rounds of refinishing.

This high purity material is 99.92% pure iron and has gone through rigorous homogeneity testing, as well as trace element analysis with GDMS, ensuring that the sample you receive will produce consistent results, and will not adversely affect the quality of your calibration curve. The high purity metal allows for a zero point correction for all of the tramp elements in the method, ensuring good quality data even at the low end of the calibrated range.

Want to know more, visit our SUS page for a listing of all of our available Set Up Samples

Check out our on-line search database or download our catalog