If you analyze aluminum materials using Spark OES, you are likely familiar with set up samples (SUS). They can be crucial for your daily operation, and ARMI | MBH now has 3 new Aluminum Set-Up-Samples to offer you.

All optical emission spectrometers are prone to some degree of intensity drift over time, and because these techniques are comparative, this drift needs to be measured and corrected in order to maintain high quality analytical results. The best correction occurs when you can measure both low and high concentrations to correct the slope and intercept of the curves.

.jpeg?width=389&name=image1%20(2).jpeg)

An SUS is a sample that is typically run on your spark system daily to correct the slope and/or intercept of the calibration lines, correcting for any change in intensity that occurs in the system from day to day. A good SUS is a homogeneous material that will produce a consistent signal over time, meaning that any observed variation in the signal can be assumed to be due to instrument drift, which is then corrected using an intensity factor. In the analysis of Aluminum, three samples are often used to cover the widest possible range of analysis from very clean samples of high purity Aluminum, to Al based alloys with relatively high concentrations of other alloying elements. Obtaining stable samples to cover this wide analysis range is critical for good long-term precision of all of the elements in the method. Once suitable samples are located, daily analysis equates to a high sample usage, and a can result in a high replacement rate for the material.

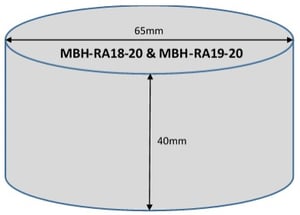

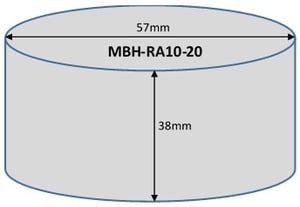

ARMI | MBH is proud to introduce three new SUS samples for Aluminum; MBH-RA10-20, MBH-RA18-20 and MBH-RA19-20. The composition of these samples is based on compositions that are commonly used in the Aluminum industry, and we have ensured a dependable supply chain by developing these samples with a large lot sizes and a dependable supply chain for future lots. The MBH-RA10-20 is offered as a 57mm diameter with 38mm height, and MBH-RA18-20 and MBH-RA19-20 are both 65mm diameter and 40mm height. The generous size of these disks provides a large surface for multiple sparks, and sufficient height to allow for numerous rounds of refinishing. These products are available individually or as a set of three.

All three of these materials have gone through rigorous homogeneity testing, using a multiple analytical techniques to ensure that the sample you receive will produce consistent results, and will not adversely affect the quality of your calibration curve. The high purity metal of the MBH-RA10-20 allows for a zero point correction for all of the tramp elements in the method, while the MBH-RA18 and MBH-RA19 allow for optimum correction for the slopes of these elements, ensuring good quality data from the low through the high end of the calibrated range.

Want to know more, visit our SUS page for a listing of all of our available Set Up Samples

Check out our on-line search database or download our catalog