The production of metal alloy parts is increasing being done using additive manufacturing (3D printing) processes. These production processes usually use a metal alloy powder that is fused by a laser in depositional layers 30-50um thick by a 3D metal printer. This technology is being increasingly used for mission critical applications in the aerospace medical industries. Verifying the quality of the powder material is an important quality control step in the process. Our certified reference materials can assist with that process.

Our CRM’s are produced from metal powders used in fusion bed printing process and are certified for a range of major and trace elements as well as provide informational values for additional trace elements. All of our CRM's are produced using our ISO 17034 accredited process.

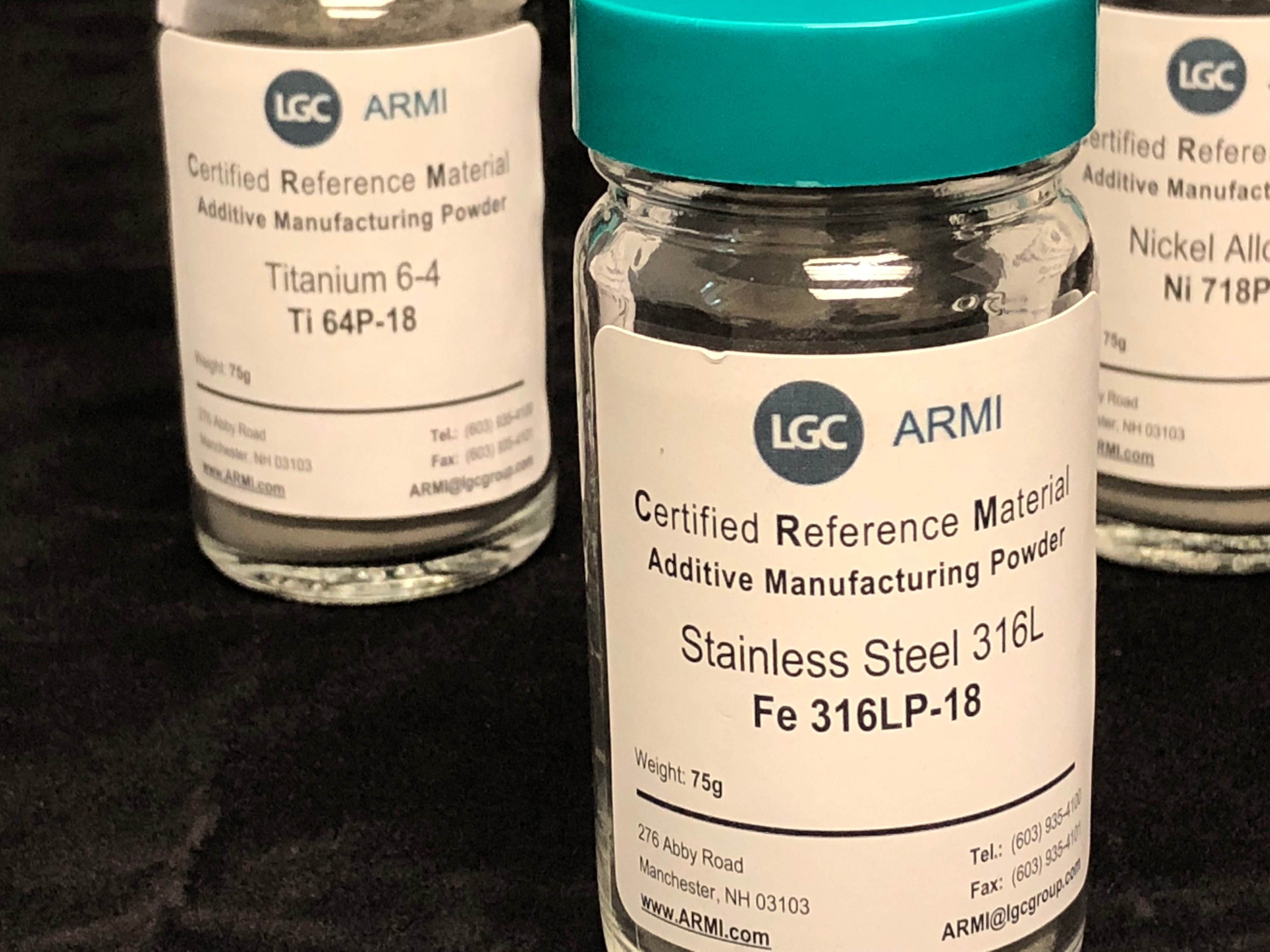

These reference materials are available for the most common metal alloy grades used in the additive manufacturing process including stainless steel 316L, Inconel 718 and Titanium 6-4.